When it comes to shipping, gross weight and net weight always seem to hog the limelight—like the lead actors on stage. But there’s an unsung hero quietly working behind the scenes, saving you money, streamlining your operations, and keeping your shipments compliant. Meet Tare Weight—the backstage genius you’ve probably underestimated.

So, what exactly is tare weight? Simply put, it’s the weight of the packaging, container, or vehicle without the product inside. Think of it as the empty box, pallet, or shipping container before it’s loaded. Doesn’t sound glamorous, right? But here’s the twist: mastering tare weight can unlock smarter, leaner, and more profitable shipping decisions.

In this blog, we’re going to break it all down. You’ll learn how tare weight is calculated, why it matters way more than most people realize, and—most importantly—how you can leverage it to cut costs, boost efficiency, and avoid costly shipping surprises. Whether you’re a shipper, a logistics manager, or a business owner trying to make sense of freight bills, this guide will help you see tare weight for what it truly is: a game-changer in your supply chain strategy.

What is Tare Weight? The Empty but Essential Weight

Let’s be honest—most of us don’t think twice about what an empty box, barrel, or pallet weighs. After all, it’s just packaging, right? But in shipping and logistics, that so-called “empty” weight—officially known as Tare Weight—can make or break your cost efficiency.

By definition, tare weight is the weight of the empty packaging, container, or vehicle without the goods inside. Imagine an empty cardboard box before you toss in your products, a barrel before it’s filled with liquids, a pallet waiting to be stacked, or even an empty 40-foot shipping container. That’s tare weight.

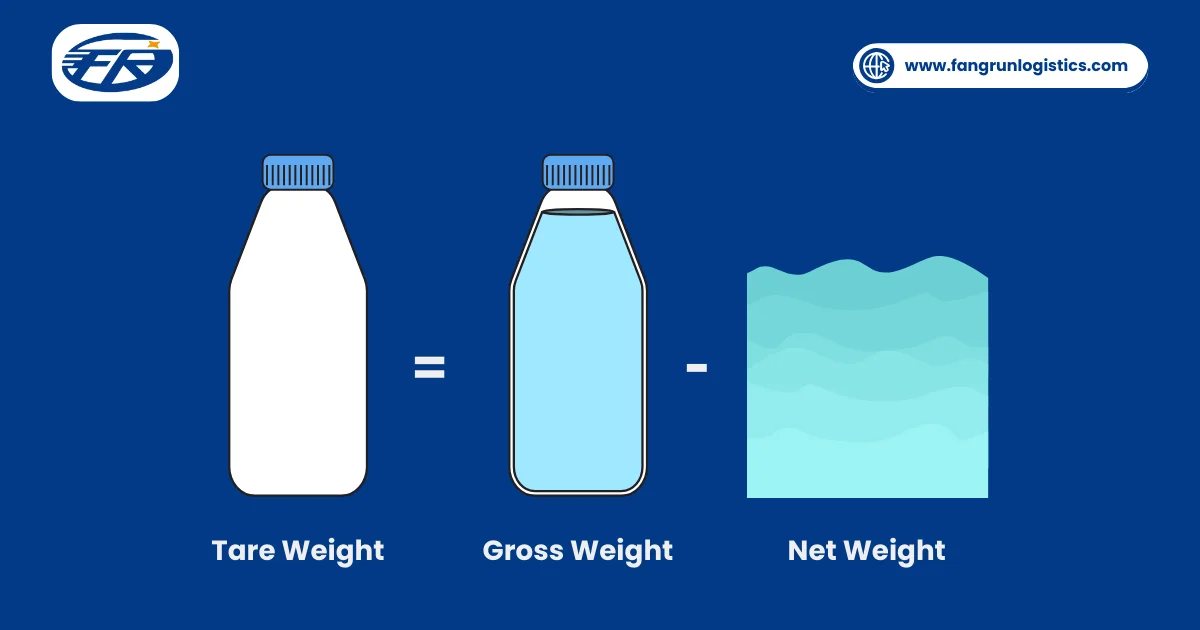

Here’s how it connects to the other “big players” in shipping math:

◉ Gross Weight = Net Weight + Tare Weight

◉ Which means… Tare Weight = Gross Weight – Net Weight

Sounds simple enough, right? But here’s the kicker: tare weight is often the hidden weight people ignore. And ignoring it can cost you—literally. For example, an empty 40-foot shipping container alone can weigh around 3,700–4,200 kg. That’s before you add a single item inside. If you shrug it off as “negligible,” you could be under-declaring weight, overpaying on freight, or worse—breaking compliance rules.

Think about it: if you’re shipping 500 pallets and each pallet adds an extra 20 kg of tare weight, that’s 10,000 kg of “invisible” weight right there. Suddenly, that “just packaging” doesn’t look so small anymore, does it?

This is why tare weight, though often overlooked, is absolutely essential. It’s the quiet number in the equation that keeps your shipping calculations honest, your compliance intact, and your logistics costs under control. Ignore it, and you’re basically inviting errors, delays, and unnecessary expenses into your supply chain.

How to Accurately Determine Tare Weight

When it comes to shipping, logistics, and inventory management, tare weight isn’t something you want to guess. Getting it wrong can mess up freight costs, customs declarations, and even safety compliance. The good news? Determining tare weight is pretty straightforward if you use the right method. Let’s break down the most common (and reliable) approaches.

1. Direct Weighing – The Gold Standard

The most accurate way to determine tare weight is also the simplest: weigh the empty packaging, container, or vehicle on a calibrated scale.

Steps for Accuracy

◉ Make sure it’s completely empty. A forgotten handful of packing peanuts or a few drops of liquid in a drum can add up and distort the numbers.

◉ Include everything that counts. Don’t forget lids, straps, inner linings, or any other components that ship with the packaging.

◉ Use a calibrated scale. Accuracy matters. A small miscalculation may not seem like much, but across hundreds of shipments, it adds up fast.

📦 Example: If you’re shipping goods in a cardboard box with bubble wrap and tape, you need to weigh the entire empty box (including all the wrapping materials). Only then will you know the true tare weight.

Think of this like weighing yourself at the gym. If you keep your shoes on, hold a water bottle, and forget about your phone in your pocket, you’re not getting the real number. Same principle applies to tare weight.

2. Manufacturer’s Specifications – The Time-Saver

For standard items like shipping containers, steel drums, or pallets, you don’t always need to bring out the scale. Most manufacturers provide tare weight data either:

◉ Printed (or stenciled) directly on the container

◉ Listed in the product specifications or manuals

Real-World Examples

◉ A standard 20-foot shipping container has a tare weight of around 2,200–2,400 kg.

◉ A standard wooden pallet weighs about 15–25 kg, while a plastic pallet might be lighter.

This method saves time when dealing with bulky or heavy equipment. Just be cautious—specifications can vary, and containers may get heavier over time due to repairs, modifications, or wear and tear.

3. Estimation – The Last Resort

Sometimes, weighing isn’t possible. Maybe your container is thousands of miles away, or you’re working with historical data. In such cases, businesses often rely on estimated tare weights based on industry averages.

Why It’s Risky

◉ Estimation can be way off, especially for irregular or customized packaging.

◉ Inaccuracies can lead to compliance issues, unexpected charges, or delays at customs.

That’s why estimation should only be used when direct weighing or manufacturer’s data isn’t available—and never for critical shipments.

📌 Example: A company shipping barrels of chemicals might assume each barrel has a tare weight of 10 kg, but if some barrels have absorbed moisture, the real tare weight could be 12–13 kg. Across 500 barrels, that’s a significant error.

4. Why Regular Verification Matters

Here’s the hidden truth about tare weight: it doesn’t always stay the same.

◉ Wooden pallets can absorb moisture and gain extra weight.

◉ Containers may rust, warp, or accumulate residues.

◉ Packaging may wear down or be altered during repairs.

If you’re shipping high volumes or sensitive goods, these changes can cause serious inaccuracies over time. That’s why it’s smart to periodically re-weigh empty containers to ensure your tare weight data is still valid.

Think of it like servicing your car. You don’t wait until it breaks down on the highway—you check it regularly to prevent disaster. Same rule applies here.

Accurate tare weight is not just a number—it’s a critical factor that influences freight charges, compliance, safety, and efficiency.

◉ Best method: Direct weighing (most accurate).

◉ Next best: Manufacturer’s specifications (convenient for standard items).

◉ Last resort: Estimation (only when you have no other option).

◉ Always: Re-check tare weight periodically to prevent costly mistakes.

👉 Bottom line: Mastering tare weight isn’t about crunching numbers—it’s about protecting your business from hidden costs and compliance risks while keeping shipping operations smooth and stress-free.

Gross Weight vs Net Weight vs Tare: Explained with Examples

Why Mastering Tare Weight Leads to Smarter Shipping Success

When most people think of shipping efficiency, they imagine bigger trucks, faster planes, or slicker software. But here’s the thing: sometimes tiny details—like tare weight—unlock massive gains. By understanding and managing tare weight, you can cut costs, boost safety, and even go greener. Let’s break down why this “empty” weight is anything but insignificant.

1. Optimizing Freight Costs 💰

Here’s a secret carriers don’t shout about: they often charge you based on the higher of gross weight or volumetric weight. That means if your gross weight goes up because of unnecessary tare weight, so does your bill.

The Power of Small Changes

◉ Lighter tare weight = lower gross weight = potential cost savings.

◉ Maximize payload: When you know the exact tare weight, you can calculate exactly how much cargo you can load without busting legal gross weight limits. More product per shipment = fewer shipments = big savings.

📦 Example: Imagine shaving just 200 grams off the tare weight of each carton. Doesn’t sound like much, right? But if you’re shipping 10,000 cartons, that’s 2,000 kg less weight. That’s a whole extra pallet’s worth of goods—or a few hundred dollars off your freight bill.

2. Ensuring Safety & Compliance ⚖️

This is where tare weight goes from “money-saver” to “life-saver.”

1. SOLAS Verified Gross Mass (VGM): In maritime shipping, the Safety of Life at Sea (SOLAS) Convention requires a Verified Gross Mass declaration for every container. Translation? If your tare weight is off, your VGM is off—and that can ground your container at the port or land you a fine.

2. Road, Rail, and Air Legal Limits: Exceeding weight limits isn’t just a paperwork headache. It’s a safety risk—think blown tires, unstable loads, or even accidents. Miscalculating tare weight could mean unknowingly overloading a truck or aircraft.

3. Accident Prevention: Accurate tare weight ensures proper weight distribution during handling and transit. No one wants a forklift tipping over or a container shifting mid-ocean.

🚛 Example: A logistics company once underestimated container tare weight by just a few hundred kilos. The result? The truck was overloaded, fined at a weighbridge, and the entire delivery delayed by days. One small tare error = thousands lost.

3. Precise Inventory Management 📊

Tare weight doesn’t just affect shipping—it also plays a big role in inventory accuracy.

◉ It ensures you’re recording the true net product weight, not inflated numbers.

◉ It helps with inventory valuation, sales reporting, and stock management.

◉ It prevents those frustrating discrepancies between physical stock and ERP system records.

Think of it this way: if you’re running tight margins, you can’t afford to let your packaging weight distort your numbers. Accurate tare weight = crystal-clear inventory.

4. Customs Declarations & Duties 🛃

Customs can be a nightmare if your paperwork doesn’t match your shipment. While duties are usually calculated on net weight, tare weight still plays a supporting role.

Accurate tare data ensures your gross, net, and tare numbers add up perfectly. That means fewer questions from customs officers, fewer delays at the border, and zero unexpected fines.

📌 Pro tip: Customs loves consistency. If your gross minus tare doesn’t equal net, expect red flags.

5. Environmental Impact & Sustainability 🌍

In today’s world, shipping isn’t just about speed—it’s about responsibility.

How Tare Weight Helps the Planet

◉ Reduced material use: By choosing lighter packaging or reusable containers, you shrink tare weight and waste.

◉ Lower fuel consumption: Every extra kilogram burns more fuel. A lighter gross weight = less fuel = smaller carbon footprint.

🌱 Example: One major retailer swapped out traditional wooden pallets for lighter, reusable plastic pallets. Result? 20% reduction in tare weight, translating to millions saved in fuel and a measurable cut in CO₂ emissions.

Mastering tare weight isn’t about obsessing over “empty” numbers—it’s about unlocking smarter, safer, and more profitable shipping.

◉ Cut costs by reducing unnecessary tare.

◉ Stay compliant with SOLAS, road, rail, and air laws.

◉ Keep inventory accurate and customs happy.

◉ Do your part for the planet while saving money.

👉 Bottom line: If gross weight is the star and net weight is the supporting actor, tare weight is the backstage crew making the whole show possible. Overlook it, and your shipping success story might flop.

Strategies to Leverage Tare Weight for Shipping Success 🚀

By now, you already know tare weight isn’t just some boring number stamped on a container. It’s a powerful lever you can pull to save money, stay compliant, and run smarter logistics. But the real question is: how do you actually make tare weight work for you?

Here are six tried-and-true strategies that turn tare weight from “empty weight” into a game-changing tool for success.

1. Choose Lighter Packaging Materials 📦

Not all packaging is created equal. Sometimes your product is traveling first-class inside a bulky, overweight box that does more harm than good.

◉ Switch to lighter cardboard, plastics, or composite materials that offer protection without unnecessary heft.

◉ Explore minimalist packaging designs. Less filler, less padding, and no “box inside a box” gimmicks.

💡 Example: A beverage company shaved 10% off freight costs just by moving from thick glass bottles to lightweight PET plastic. The products were still safe, but the lighter tare weight reduced overall shipping costs.

2. Utilize Reusable Packaging (Think Circular Economy) 🔄

Why keep paying for disposable, heavy packaging when you can invest in something reusable?

◉ Durable, lightweight, reusable containers are perfect for closed-loop supply chains.

◉ Cuts down on long-term tare costs while also slashing environmental waste.

🌱 Real-world win: IKEA famously switched to reusable, stackable transport packaging for suppliers, reducing packaging weight and saving millions in logistics costs annually—all while keeping sustainability at the core.

3. Standardize Your Packaging 🎯

Chaos in packaging = chaos in tare weight.

By using consistent packaging for similar products, you:

◉ Simplify tare weight calculations.

◉ Optimize truck/container space.

◉ Make staff training easier.

Imagine if every shipment had random box sizes and weights—you’d waste time, space, and money. Standardization keeps tare weight predictable and efficient.

4. Implement Regular Tare Weight Audits 🧐

Here’s a sneaky truth: tare weight isn’t static. Packaging can change over time—wooden pallets absorb moisture, containers wear down, and materials degrade.

That’s why it’s crucial to re-weigh empty packaging periodically.

◉ Update your tare weight databases regularly.

◉ Avoid surprises when your gross weight suddenly doesn’t add up.

🔧 Pro tip: High-volume shippers should schedule quarterly tare audits. It’s like giving your logistics system a health check-up.

5. Educate Your Team 👨🏫

Tare weight isn’t just the responsibility of the logistics manager—it’s a team effort.

◉ Train staff on why tare weight matters.

◉ Teach them how to handle it accurately in packing, weighing, and recording.

🎯 Example: One warehouse reduced discrepancies by 40% after training staff on proper tare handling. Sometimes, success is just about making sure everyone’s on the same page.

6. Invest in Accurate Scales ⚖️

Let’s face it: if your scales are dodgy, your tare weight data is worthless.

◉ Use calibrated, high-quality weighing equipment suitable for the range of weights you’re dealing with.

◉ Don’t rely on outdated or overloaded scales—they can skew results and ruin your compliance or cost-saving efforts.

💡 Pro tip: Even airlines replace or recalibrate their scales regularly because a small error in weight can lead to massive cost and safety issues. If they take it seriously, so should you.

Leveraging tare weight isn’t about reinventing your logistics system—it’s about making smart, practical tweaks that deliver huge payoffs over time.

◉ Lighter, reusable, and standardized packaging saves money.

◉ Regular audits and accurate scales prevent costly errors.

◉ Educated teams keep the system running smoothly.

👉 In short, master your tare weight, and you master your shipping success.

Conclusion: The Power of the “Empty” Weight

At first glance, tare weight might look like just another number in the shipping equation—an “empty” detail. But as we’ve uncovered, mastering this concept is actually a strategic lever that unlocks big wins: significant cost savings, airtight compliance, and overall smarter, more profitable logistics operations.

When you pay attention to tare weight, you’re not just trimming ounces—you’re maximizing payload, preventing costly errors, and fueling a leaner, greener supply chain. In short, ignoring tare weight leaves money and efficiency on the table, while mastering it fills your shipments with fuller profits and smoother operations.

Call to Action: Take the First Step Today 🚀

So here’s your next move:

✅ Audit your current packaging and tare weight practices. Are you weighing accurately? Are your materials heavier than they need to be? Could reusable or lighter options save you money?

✅ Start small, think big. Even minor adjustments in tare weight today can add up to massive cost and compliance benefits over time.

And if you’re ready to take tare weight optimization seriously, Fangrun Logistics is here to help. From lighter, sustainable packaging strategies to smarter shipping solutions, we’ll make sure your “empty” weight turns into full-blown success.

👉 Contact Fangrun Logistics today to discover how you can cut costs, boost efficiency, and ship smarter.